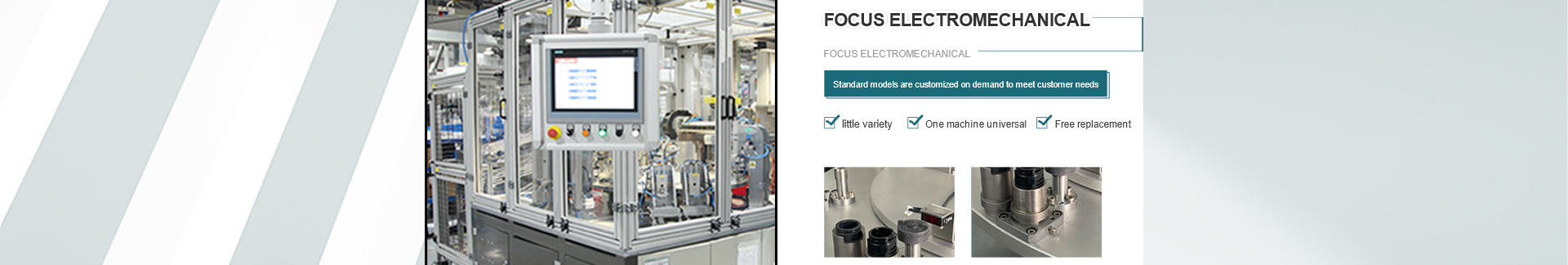

Twenty years of focus: small amount, variety, no change, quick change!

Let the manufacture of high quality no longer depend on people!

Hotline

13773187198

Let the manufacture of high quality no longer depend on people!

13773187198

Non-standard automated assembly machines can be divided into three types according to their structure:

(1) The flexible assembly unit uses one or more robots to complete various assembly work in a fixed station according to the program;

(2) The multi-station flexible synchronization system system consists of a fixed or dedicated assembly line composed of a transmission mechanism, which is controlled by a computer, and has its own programmable program and optional station, so it is flexible;

(3) Flexible automatic assembly machine with combined structure This structure is composed of equipment, tools and control devices required for assembly, which can be enclosed or placed in a protective device.

1. Detection process

The inspection process includes inspection, inspection and testing of the assembled parts. On the one hand, the inspection process ensures the quality of the assembly, such as whether the loaded parts are defective, whether the loaded parts are in the correct direction and position, the dimensional accuracy after loading, the sealing quality, and the assembly. quality, etc. On the other hand, various faults are dealt with during the assembly process.

2. Adjustment process: The adjustment process is to correct the position of the components with installation deviation after the assembly process.

3. Auxiliary process: Auxiliary process includes cleaning, marking, sorting and other links of assembly parts.

4. Machining process: On some automatic assembly equipment, one or several specific parts are also machined during the process of installing and fixing parts.

Wechat: Siyuan longzhizao

Q Q:236259351

Tel: 13773187198

Mailbox:syl@sylfocus.com

Website:southbedding.com.cn

Address: No. 299, Weihan Road, Zhoushi Town, Kunshan City